You know the feeling. A critical piece of equipment on the factory floor starts beeping an incomprehensible error code. A customer is on the phone, desperately trying to describe a blinking light on their new smart home device—”It’s kind of… red, but also a little orange?”—and you’re flying blind. For decades, this has been the frustrating reality of remote support. It’s a game of telephone crossed with a high-stakes puzzle, where miscommunication costs time, money, and customer loyalty.

Well, that era is over. Enter Augmented Reality (AR). This isn’t about sci-fi goggles for gaming; it’s a practical, powerful tool that’s completely reshaping how we solve problems from a distance. AR-powered remote support is, quite simply, turning the invisible into the undeniable.

What Exactly Is AR-Powered Support? It’s Like X-Ray Vision for Your Techs

Let’s break it down without the jargon. Imagine a field technician, a customer, or even a maintenance worker in your own plant. They point their smartphone or tablet at a malfunctioning machine. Through the camera, they see the real world. But layered on top of it are digital instructions—floating arrows, highlighted components, step-by-step animations, or live video feed from an expert hundreds of miles away.

It’s the difference between someone telling you, “The valve is on the left,” and you seeing a giant, glowing digital circle around the exact valve you need to turn. This is the core of AR for troubleshooting. It merges the physical and digital worlds to provide contextual, visual guidance right where the work is happening.

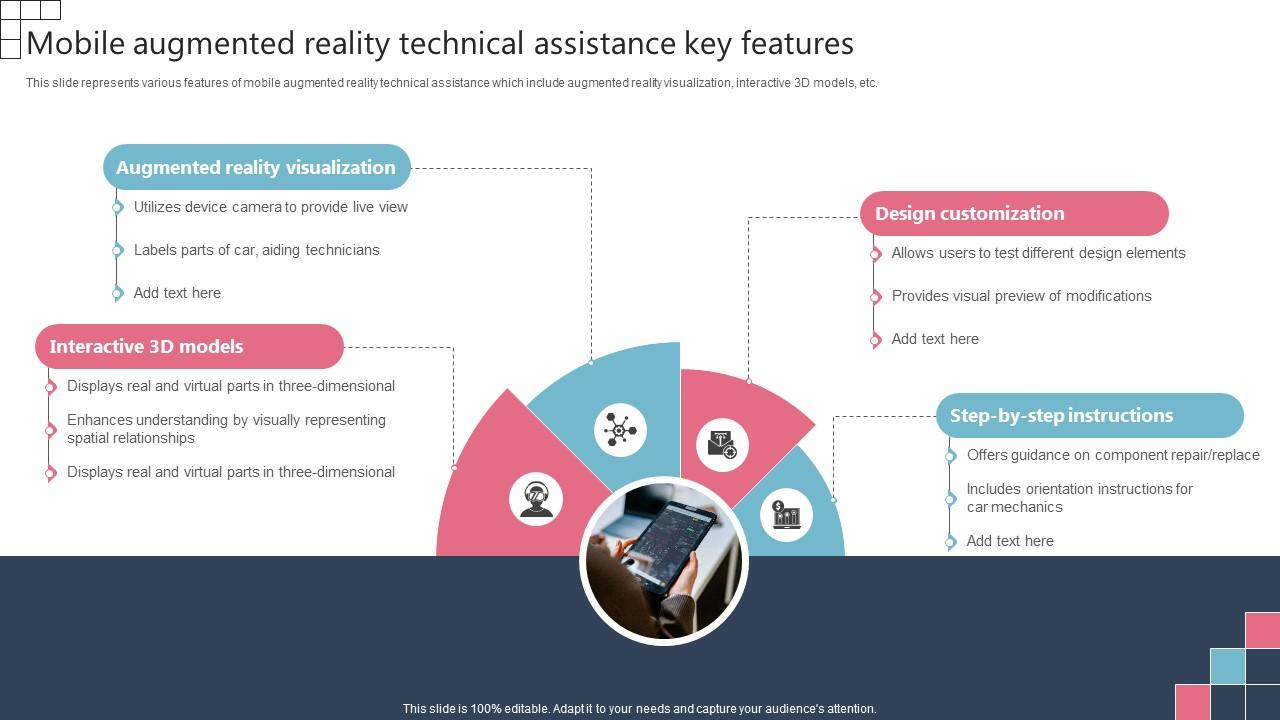

The Magic Happens Here: Core Functionalities

So, how does this wizardry actually work in practice? The magic is in a few key features that make support sessions incredibly efficient.

- Visual Overlays and Annotations: An expert can draw directly onto the live video feed from the user’s device. A simple circle around a loose cable, an arrow pointing to a reset button, text saying “Turn this knob clockwise.” It’s instant, unambiguous communication.

- 3D Digital Twins and Animations: For complex procedures, a 3D model of the product can be superimposed onto the real thing. This can show an exploded view, demonstrate the correct assembly sequence, or animate the inner workings of a mechanism that’s usually hidden from view.

- Remote Expert Live View: This is a two-way street. The on-site worker shares their camera view, and the remote expert sees exactly what they see. They can then talk them through the repair, using the annotation tools to guide them. It’s like the expert is right there, looking over their shoulder.

- Document Integration: AR apps can pull up the relevant PDF manual or schematic and pin it to a specific part of the machine. Look at the motor, and the motor’s specs appear floating next to it. No more fumbling through a 200-page document.

Why Bother? The Tangible Benefits Are Staggering

This all sounds cool, sure. But the real-world impact on business metrics is what makes it a game-changer. We’re talking about moving beyond incremental improvement to a fundamental leap in efficiency.

| Traditional Support Pain Point | How AR Solves It | The Bottom-Line Result |

| Misdiagnosis due to poor communication | Expert sees the problem firsthand via live video | Faster First-Time Fix, fewer wasted dispatches |

| Lengthy, confusing phone calls | Visual guidance cuts talk time dramatically | Reduced call handle time by up to 40% |

| Need to send a specialist on-site | Remote expert can guide a junior tech or even the customer | Slash travel costs and downtime |

| Ineffective training for complex equipment | Interactive 3D guides provide on-the-job learning | Upskilled workforce, fewer future errors |

Honestly, the numbers don’t lie. Companies implementing AR-powered remote assistance are reporting some pretty stunning stats. We’re seeing a reduction in resolution time by over 50% in many cases. And perhaps the biggest win? A dramatic drop in the number of truck rolls—those expensive, time-consuming dispatches of a technician to a site. That alone can save a company millions.

Getting Real: Use Cases Across Industries

This isn’t some futuristic concept locked away in an R&D lab. It’s being used right now, solving real problems in demanding environments.

Manufacturing & Industrial: A conveyor belt seizes up at 2 AM. Instead of waiting hours for the on-call specialist to drive in, the plant manager uses their tablet. The expert, from their home office, sees the jammed roller, annotates the specific bolt to loosen, and talks the manager through the reset procedure. Production is back online in 20 minutes.

Field Services: An HVAC technician is stuck on a rooftop unit they’ve never serviced before. They initiate an AR call with a senior engineer. The engineer pulls up the 3D model, highlights the compressor assembly, and shows the exact sequence for recalibration. The job gets done right the first time, and the junior tech gains invaluable experience.

Consumer Electronics & Smart Home: A customer can’t figure out how to install their new smart thermostat. They open the manufacturer’s app, which uses AR to show an animation of the wires being connected to the correct terminals right over their own wall plate. What was a 45-minute support call becomes a 5-minute self-guided success.

But It’s Not All Perfect… The Hurdles to Clear

Now, let’s be real for a second. Adopting this tech isn’t as simple as flipping a switch. There are challenges. The initial investment in software and, sometimes, hardware (like ruggedized tablets or AR glasses) can be significant. You need a robust, secure network connection—both on-site and for the remote expert. A laggy, glitchy video feed is worse than no video at all.

And then there’s the human element. You have to get your team, and maybe even your customers, comfortable using this new tool. Change management is a real thing. But the ROI, when calculated against the savings in travel, downtime, and improved customer satisfaction, often makes these hurdles worth jumping over.

The Future is Already Here: What’s Next for AR Support?

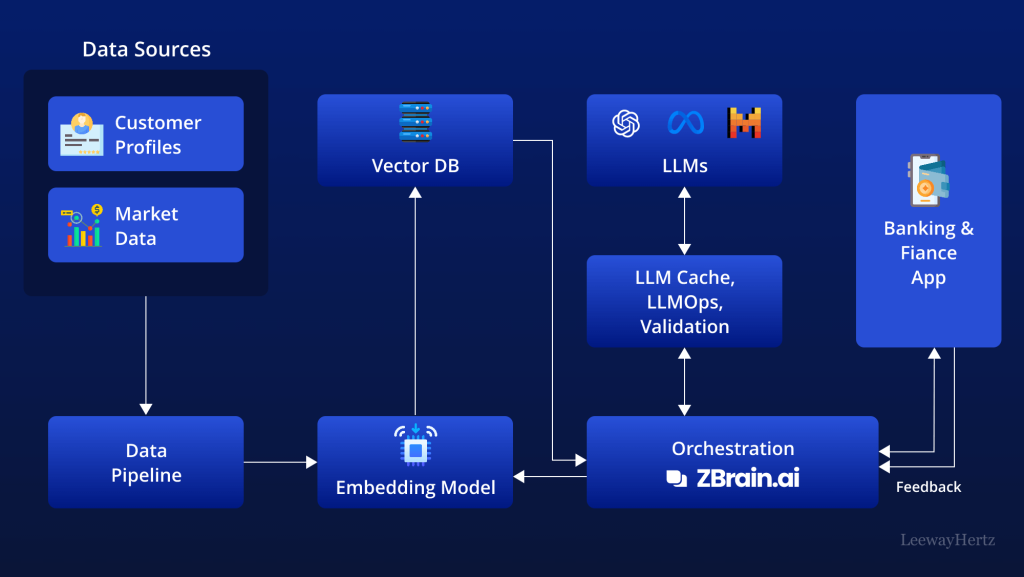

We’re just scratching the surface. The next wave involves AI integration. Imagine an AR system that doesn’t just connect you to an expert, but is the expert. A system that uses computer vision to automatically identify a worn-out part, cross-reference it with the inventory system, and display an animation of the replacement procedure—all without human intervention.

Or consider the rise of spatial computing and more advanced wearables. Hands-free AR glasses will become the norm, allowing technicians to perform complex repairs with digital instructions hovering in their field of view, leaving their hands completely free to work.

The gap between seeing a problem and solving it is closing fast. AR-powered support is bridging that final mile, transforming frustration into clarity and guesswork into precision. It’s not just a better way to do support; it’s the beginning of a new language for collaboration, one where we all have the tools to see the solution, together.